6. Working Storage

Topics in this section :

6.1. Interdependencies of ’sequencers’.

6.2. Working storage as a construct.

6.2.1. Relation to task, relations between variables.

6.2.2. Multidimensional constructs.

6.3. Mechanism - working storage structured by its place in task thinking.

6.4. Updating the data in working storage.

6.4.1. Updating the main control state.

6.4.2. Updating the data on the general state of the process.

6.4.3. Handling interrupts.

6.5. Working storage capacity.

Section 6 : Working storage

Building up behavioural complexity from a cognitive processing element.

Lisanne Bainbridge

This Section focusses on what the operator knows about the current state of the task they are doing, which includes the recent past and near future.

The first part is about what can be in this working storage (which may be called the 'mental picture'), and what is the mechanism for keeping it in mind.

Then there are comments on updating this mental description of the task, and its capacity.

The main reasons for suggesting that someone doing a complex task builds up an 'overview' which is referred to when deciding on the sequence of behaviour, and the place of that overview in a cyclic rather than serial model of cognitive processing, were introduced in Table 4.4 and Sections 4.2 and 4.4.

repeat of Table 4.4

In summary : in Table 4.4, columns A and B are much the same, though they were derived from independent analyses :

A : the items found by each of the main 'routines' (analytic technique described in Section 2).

B : the items identified as determining the choice of what to think about next (analyses done after A, analytic technique described in Section 4.1)

Looking at this the other way round : as the two columns are much the same, it is possible to suggest the items needed by the sequencers are found by the main routines. So the B items were included in the 'sequencers', at the head of 'routines'. The main routines build up a representation of the current state of the task, which is ’stored’ in the sequencers as an overview of the task, which is referred in deciding what to do next.

Section 4 introduced the notion that the working storage of a person doing a complex task contains this overview, which is both the result of thinking about the task and also acts as the context for later decisions on what to think about next and what to do.

This section gives some more detail in support of this overview idea. Plus relating it to some memory concepts used (at the time) in experimental psychology. Also Section 6.4.1 mentions some additional mechanisms needed to account for all aspects of what working storage can do.

-

6.1. Interdependencies of 'sequencers'

What are the sequences of 'sequencers' ?

Several main 'sequencers' were needed to describe the factors determining the order in which the operator mentioned topics in his protocol. The most frequently occurring 'sequencer' was OVERALL (see Figure 5.2). This is not surprising, as the operator's task is to control the power usage, and the OVERALL 'sequencer' finds out what the control error is, and determines what should be thought about next on the basis of it.

Figure 6.1 summarises how the 'sequencers' follow each other, as observed in the furnace power controller protocol data.

Figure 6.1 : Any one 'sequencer' may be followed by several other 'sequencers'.

Arrows in this diagram show that one sequencer is followed by one or more others, e.g. OVERALL may be followed by ONGOING, UNACCEPT, or STEP CHANGE.

Note at a quick glance this diagram looks like a serial process, but actually the top and bottom are the same item, it describes a cycle. (And the thinking returns to assessing the control state - OVERALL - more often than implied by this diagram, see Section 6.4.1 below on updating.)

It has been suggested in Sections 4 and 5 that the main data, the results of finding the main cognitive needs, are in a general overview form of working storage, which is continuously available to all processing rather than local to particular 'routines'. Figure 6.2 below shows evidence from the furnace operator simulation which supports this possibility.

Figure 6.1 above summarises how 'sequencers' follow on from each other.

In Figure 6.2, the 'sequencers' are laid out in the same positions as in Figure 6.1, but the arrows show how the 'sequencers' make use of, i.e. cross refer to, data found by other 'sequencers', e.g. UNACCEPT uses data found by/ cross refers to OVERALL, ONGOING, UPDATE, and END TIME.

Figure 6.2 : Sequencers refer to data in working storage which has been found by other 'sequencers'.

Layout as in Figure 6.1, but in this Figure the arrows indicate how sequencers make use of information found by other sequencers.

This shows clearly that processing when the control state is unacceptable makes extensive use of data obtained when the control state was acceptable (such as which furnaces are doing what, what is likely to happen in the near future, what effect this will have on the control situation, and what to do about it, see Section 6.4). This suggests that the 'sequencers' do not fall into distinct groups which have no relation to each other (i.e. the sequencers used when the control state is acceptable are not completely separate from the ones used when it is unacceptable). Instead it is possible that they all operate within the same general overview. However, there is not one big 'sequencer', as the 'sequencers' in Figure 6.1 are independent in the sense that they can either follow or be followed by several other 'sequencers'.

As mentioned before, e.g. in Section 3a, information needed may have been found by another routine elsewhere. As noted in Figure 6.2, the UNACCEPT sequencer (which describes the thinking done when control state was unacceptable) uses data found by/ cross refers to OVERALL, ONGOING, UPDATE, and END TIME. This is shown by double arrows in relevant boxes in most figures. It is emphasised by red arrows in the next Figure.

Figure 6.3, annotated version of Fig 5.3 : UNACCEPT sequencer, red arrows show cross references to data found by other ’sequencers’ (shown in other diagrams by double line arrows, which are less obvious).

Inversely, the data found by one sequencer may be made use of by several others, e.g. UPDATE finds data later referred to by UNACCEPT (Figure above) and by ASSESS sub-routine 6.a (Figure 6.12), which are both part of thinking about future events and the effect they will have on the control state.

Figure 6.4 - annotated version of Figure 6.10 below : UPDATE sequencer. Red boxes show results of cognitive processing which are referred to by other sequencers.

The items in the red boxes need to be available (i.e. remembered after the operator has finished working through the thinking described by this 'sequencer'), as they are referred to when thinking about other issues.

In a box element representation of cognitive processing, the overview is made up of what is in the working storage boxes associated with the main cognitive needs, which are located in the 'sequencers'. The 'sequencers' refer to these items when they make decisions about what best to do next. This overview is called 'situation awareness' in many studies of complex tasks.

This leads to a contextual model of cognitive processing in complex tasks. Sequencing decisions, made by the conditional elements in the 'sequencers', lead to the use of 'routines', which update the working storage overview. This overview then acts as the context for (i.e. provides the data for) the sequencing decisions, and so on. This can be summarised by the cycle models in Section 4. The most simplified diagram of this cycle is Figure 4.5. Figure 4.6 shows, again greatly simplified, how this basic cycle interacts with the environment and with knowledge, and how highly salient information in the environment can override the current thinking (attract attention). The actual operation of the cycle can be represented by the cognitive elements in the 'sequencers' calling on 'routines'. So context effects which determine the flexible sequencing of behaviour can be accounted for by the proposed mechanism. More on the updating process in Section 6.4.

-

6.2. Working storage as a task-related construct

(The rest of this section has frequent references to my note on Working Storage in Air-Traffic Control.)

Data from complex tasks shows clearly that what is in working storage is a construct : what is kept in mind temporarily is the result of thinking about the task, not an untransformed representation of input data (e.g. Tables 2.2 and 2.3 in Section 2). Indeed, it has been called working 'storage' to underline this difference from some models of short-term memory.

The box element mechanisms are sufficient to account for working storage in tasks like furnace power control, in which it is simple to represent the structure of what is in working storage, as the different items to be remembered are independent single variables. But the box element representation is no more able to handle patterns of data than most other fully specified methods. And evidence from other tasks shows that the working storage mechanism does need to be able to represent multidimensional constructs and interrelations. The rest of this subsection does not suggest what these mechanisms might be like, it just gives some typical examples of the data which needs to be dealt with by a more complete account : some richer types of construct which are involved in other complex tasks.

6.2.1. Relation to task, relations between variables

Data from air traffic control (Bainbridge, 1975) shows clearly that what the controllers remembered was related to their task thinking. There was also anecdotal evidence that they remembered not individual items but items relative to each other and to the task criteria.

Figure 6.5 : Numbers of items about the aircraft they are controlling remembered by air-traffic controllers (data from Bisseret, personal communication based on Bisseret, 1970). (Bainbridge, 1975 , Figure 1)

Bisseret (1970) found that experienced air-traffic controllers could remember an impressive number of facts about aircraft they had just been controlling, over 30 as shown above. The bottom graph shows this number is related to the controller’s experience and their workload. Increased number of aircraft means there were more items to which might be remembered, but this doesn’t necessarily lead to more items actually remembered, it only does so for the most experienced controllers. Though the trainees and just qualified controllers remember 2-3 times more items than 7±2, the short-term memory capacity found in laboratory studies of remembering random items without meaning (Miller, 1956).

Bisseret also found that the frequency with which controllers remembered a particular type of fact describing an aircraft (its height, direction, or speed, for example) correlated with the sequence in which these items were thought about while checking for aircraft which were too close together/ 'in conflict' (this sequence was identified by Leplat and Bisseret, 1965). This finding could be explained by the recency and repetition effects found in laboratory studies of short-term memory.

Though air-traffic controllers' memory does involve more complex mechanisms. Bisseret studied controllers using paper flight strips, each of which describes one aircraft (this 'technology’ is no longer used). Bisseret collected anecdotal evidence about how the controllers remembered the aircraft, which suggests that these items are not remembered as raw data about individual aircraft, as displayed by the strips. He found that the controllers, when asked to draw a map of where the aircraft were, would make remarks like 'I've got one at level 150 which is about to pass beacon RLP and another at level 170 which is about 10 minutes behind so is about here'. This suggests that the controllers remember the aircraft, not in isolation but in terms of the relations between them which are important for their task (identifying aircraft which are too close together). The controller has found these relations, such as which aircraft are going in the same direction, their relative height, and the distance between them, as the result of thinking about the task (using the strategy identified by Leplat and Bisseret op cit). The controllers' working storage is a construct of relations. Any representation of the air-traffic controllers working storage (or 'operational' memory, as Bisseret calls it) would have to represent at least these relative positions in space-time.

Chess playing is another task in which the representation in working storage needs to include relations between items. Chase and Simon (1973) for example found that, when faced with a random layout of pieces on a chess board, both expert players and non-players remembered the same number of items. However, when the pieces were laid out as in a real game, expert players remembered the layout more fully, and remembered it in terms of game-related analytic features, such as attack, defence, and the quality of the positions and therefore likely quality of the players.

So the mechanism for working storage needs at least to be able to contain relational information.

These points about storing relations raise a question about the nature of working storage. Section 2, introducing the box element, pointed out that the working storage box should not be taken as a location to which items are transferred for storage, but rather as a type of link. The simplest mechanism for working storage would be for it to 'point to' or activate a representation of the relevant item which is already in long-term storage, in the knowledge base (Hebb, 1949). However, such a mechanism would not be able to account for new structures of relations to describe situations which have not previously been experienced. These may be built up in working storage and then become part of the knowledge base. Perhaps two types of mechanism are needed, to account for remembering in well known and in unfamiliar situations (see Section 8), though it would be simpler if the behaviour in well known situations could emerge from the mechanism for behaviour in unfamiliar situations after much repetition.

There is no evidence about such questions from the furnace power control task data.

6.2.2. Multidimensional constructs

Other tasks may involve even more complex representations of the current control states.

A steelworks blast furnace is a good example of a multidimensional process within which the cause-effect relations cannot be directly observed and are not well understood. Hoc (1989) has shown that blast furnace operators build up multidimensional constructs which represent their understanding of what is happening inside the process. These mediate between the variables of the process which can be measured and displayed, and the control decisions which the operators make. Figure 6.6 below shows some examples of these multidimensional constructs.

Figure 6.6 : A blast furnace operator's influence graph (Hoc and Samurçay, 1989, Figure 1, English translation from Hoc, 1989, Figure 6).

'Unobservable' descriptors (items in the ovals) are not displayed on the interface or visible on the furnace, they are states inferred by the operator from the information which can be directly sensed (items without oval surrounds).

-

6.3. Mechanism

In his studies, Sperandio (1970) found that the number of items remembered by an air-traffic controller about a particular aircraft depended on how important the aircraft was in the current thinking.

Figure 6.7 : Number of items remembered about air-traffic controllers, relative to the controller's categorisation of the aircraft (from data in Sperandio, 1970). (Bainbridge, 1975, Figure 2)

Air traffic controllers remembered more items about aircraft which were in radio contact, Also fewest items were remembered about an aircraft which was not 'in conflict’ with another aircraft or was in conflict but not the one which was asked to change. While more was remembered about the aircraft in a conflict on which an action had been made, and most about one for which an action had been chosen but not yet made.

Both these findings might be accounted for by conventional short-term memory models in the 60-70s, in which remembering an item depends on recency and rehearsal. In both results the number of items remembered is related to the recency and frequency with which an aircraft item is likely to have been thought about.

Working storage structured by its place in task thinking

But might there be more to it in the short-term memory of experienced people doing a complex task ?

Bisseret’s data on the memory capacity of expert controllers (Figure 6.5 above) suggests there might be.

In a similar way to the way 'routines' are partially structured, or held together, by the cross references between the items ’stored' in its box elements (as discussed in Section 2, see e.g. Figure 2.7), so sequencers are linked together by cross references between the items in the boxes, which has been called the overview (example in Figure 6.3 above).

The processing element representation suggests working storage is inherently structured :

a. relative to the cognitive needs,

b. by cross-references between cognitive needs.

These cross-references have been symbolised in the Figures in three ways :

1. explicitly, e.g. Figure 2.7.

2. by boxes containing single or double arrows (e.g. Figure 2.3). The arrow is interpreted as pointing to the data needed, which is already available either earlier in the present processing (coded by single arrow) or elsewhere with another major cognitive need (double arrow in many diagrams, red arrow in Figure 6.3).

3. by boxes with a double-line contour (e.g. also 3c.1). This represents a result found by later processing, usually by a 'routine', which is then passed 'up' to the originating cognitive need.

The points made here supplement the points on working storage in Section 2, and on the main cognitive needs and the overview in Section 4. The box element mechanism shows clearly that what is in working storage is a construct : what is kept in mind temporarily is the result of thinking about the task, not an untransformed representation of input data. And it is structured by its relation to task thinking processes. Indeed, it has been called working 'storage' to underline this difference from some models of working memory.

Might these relationships/ support structures in complex tasks mean more can be remembered about the current situation than the conventional 7±2 items remembered about random material, as Bisseret’s data suggests ? There is only speculative evidence on this from the furnace power controller data, mentioned in Section 6.5.

-

6.4. Updating the data in working storage

Updating the person’s knowledge of the state of their environment is done by the 'sequencers', as 'sequencers' call on 'routines' which check the environment, as described in Sections 3a and above. So there are explicit and distinct cognitive processes, in a 'sequencer', for updating the mental representation of the present situation.

From the simplified representation in Figure 6.1 it may look as if there is no way for the processing to get started. However, this is dealt with by the two-arrow box described in Figure 3c.4. This provides a mechanism for finding information if it is not already available.

But a mechanism which only looks for information which has not been obtained before will never update that information once it has been obtained, and will assume that the external world continues in an unchanging state. Some mechanism is needed for keeping up-to-date with the changing state of the external world (any organism which moves around and did not do this would not last long !).

In the protocol from the experienced furnace power controller, this updating appears to take two forms, related to what the operator is updating. To discuss this it is useful to distinguish between two aspects of the state of the external world :

1. its state relative to the main task goal(s), e.g. in the furnace control task : whether or not the electric power usage is within acceptable limits.

2. the general state of the other parts of the external world which it is relevant to know about when thinking how to meet the main task goals, and which is used in sequencing decisions. These are data used in optimising the response to the main task goals and meeting secondary goals. For example, in the furnace control task : what each furnace is and will be doing, the effect any future changes will have on electric power usage, and on the best action to make in the future, if required.

There must also be working storage mechanisms for handling interrupts (Section 6.4.3).

—

6.4.1. Updating the control state

The furnace operator's behaviour, when checking his main task goal, is described in the simulation by the OVERALL 'sequencer', shown in Figure 5.2 and repeated below. This 'sequencer' calls on the main 'routine' for checking the control state ('routine' 1, described in Figure 5.4), and chooses the next best behaviour on this basis.

Repeat of Figure 5.2 : Choosing the most appropriate next cognitive activity, given the control state as assessed by 'routine 1' described in Figure 5.4 (Bainbridge, 1972, Figure 7.3.a).

Figure 6.1 represents the operator as checking the control state (i.e. returning to the OVERALL 'sequencer') only after working through the whole of some other 'sequencers'. However, things are not so simple. The verbal protocols show that the operator may briefly check the control error during thinking about another part of the task, and then, if the control error is unchanged, go on with the other task thinking from the point at which he left it. In a 'routine' this can happen between cognitive needs. For example, in Figures 4.3 and 4.4 (themselves simplifications), the operator may check the overall control state after checking the power levels, and then go on to looking at furnaces which were charging. In a 'sequencer', the operator may check the control state at the end of a section of processing. For example, in the ONGOING behaviour described by Figure 5.7 repeated below, the operator may check the control state at the end of each of the three branches (which can be done in any order), not just after all three have been worked through.

This interrupting to check the control state suggests that different 'sequencers' have different levels of priority, and that higher priority 'sequencers' can interrupt lower priority ones. This could be important in mechanisms to account for multi-tasking (see Section 7.4).

An inverse issue arises. Perhaps the operator does not just check the control error at the points explicitly directed in the 'sequencers' and 'routines', but checks it after meeting every cognitive need in each 'sequencer' and 'routine'. The data suggest an intermediate situation (which of course is more difficult to model).

The protocol data do not suggest that the operator returns to check the control state every time he has met any of the other cognitive needs (though there is always the possibility that this check could be done by eye movement and pattern recognition which are not mentioned verbally).

The length of time between each explicit mention of the control state can be measured from the protocol recordings. Figure 6.8 shows the frequency of different inter-sample intervals, when the control state was unacceptable (left) and acceptable (right). The data suggest that the inter-sample interval was more often longer (second mode at 5 minutes) when the control state was acceptable, though the difference between these two frequency distributions is not statistically significant.

Figure 6.8 : Frequency of different lengths of inter-sample interval in the furnace control task, when the control state was unacceptable and acceptable (Bainbridge, 1972, 7.4.3.b).

There are other studies, e.g. Crossman et al (1974), which also show that sampling rate depends on the size of control error (Figure 5 in this extract from that paper shows that the operator samples more often when the control state is settling down after a control action than during steady-state times.)

Several simple mechanisms could be suggested for this interrupting style of updating. Protocol data are not able to distinguish between these possibilities.

1. The level of the control state (the main task goal) could act as a time tag which determines how long any processing which is not directly related to the control state will continue, before the control state is checked again.

2. Alternatively, the uncertainty of the working storage representation of the control state might increase with time, see Figure 3 in Crossman et al, 1974. This certainty could be (unconsciously) checked after each cognitive need has been met. Processing would return to updating if the uncertainty was too high.

There is the possibility that there is some sort of urgency tag in the context which determines whether the operator goes on thinking about further aspects of the situation (as in Figures 4.3 and 4.4) or checks the control state. This would mean that the 'what to do next' choice mechanism can sometimes be somewhat similar to the way characteristics of the context are compared with characteristics of a working method to choose how to do something (see Section 7).

There also needs to be a mechanism for returning to the previous point in the processing if the control state is unchanged.

-

6.4.2. Updating the data on the general task state

Figure 6.9 : Left side : main interdependencies between aspects of working storage (Bainbridge 1992, Figure 1). The items have to be found in this order (green arrows).

The present control state and what is happening now on the furnaces are found by sequencers OVERALL and ONGOING.

Predicted states and actions are found by sequencers UPDATE, STEP CHANGE, ASSESS.

The furnace operator spent his time, when action was not needed (see Figure 5.2), in reviewing the general state of the process. This behaviour was described in the simulation by a 'sequencer' called ONGOING (Figure 5.7 and below). This 'sequencer' reviews the present state of the process. It leads to other sequencers : UPDATE and the associated ASSESS and its sub-routines. These predict forthcoming events, their effects, and what to do about them. They are described more fully below.

These processes have been represented as separate items as they were identified from grouped phrases in the first phase of the protocol analysis. The review of the situation which is built up in this way is then referred to during decisions about what to do next, as indicated in Figure 6.2. So there are explicit and distinct cognitive processes, in a 'sequencer', for updating the representation of the present situation.

Beishon (1969) also found that the forward plan of his oven operator included explicitly making an overall check of what was happening on the ovens.

These items don’t follow simple 'rules' for what is defined as a 'sequencer' or a 'routine' (see Section 5.2.2). For example, ONGOING contains no conditionals so is not involved in changing the direction of thinking, and ASSESS returns a single data item - which makes it like a 'routine'.

Repeat of Figure 5.7 : The ONGOING 'sequencer' used when updating awareness of the general control situation, and predicting future events and their effect on the future control state. These cognitive activities are done when the control state is acceptable (see Figure 5.2). UPDATE (see next) is an activity done in several contexts. (Bainbridge, 1972, Figure 7.3.3). [diagrams of 'routines' 5.b and 5.c are not currently available]

The left column of ONGOING builds up a 'Furnaces cut’ list - these are furnaces it would be best to make an action on if an action is needed, as the quality of steel made is least disrupted if power is cut to furnaces while they are in the melting stage, early in the stage (more baskets left), and particularly if they have previously had a power cut.

After listing the furnaces which are in quality stages (it’s important not to interrupt their power supply), or in non-power using stages (such as emptying and cleaning), the operator goes on to cognitive processing which has been labelled as UPDATE.

UPDATE, Figure 6.10, is part of what the operator thinks about when predicting future events during the current 1/2 hour. In UPDATE he identifies whether the stage a furnace is currently in will end during this half-hour. As the new stage will probably use a different amount of power, this change might affect the control target of using less than a given amount of power in any half-hour. It may be useful in control - for example, if it uses less power it may compensate for the current situation if that is using too much.

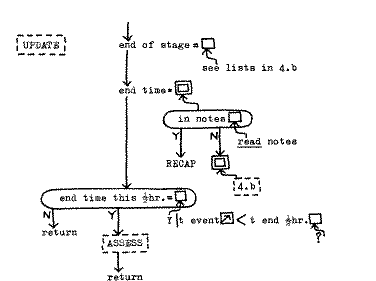

Figure 6.10 : Part of the operator’s UPDATE of his knowledge about the state of the whole process, by predicting the time of a future event and whether that time will be in this 1/2 hour. Bainbridge (1972).

UPDATE refers to routine 4.b, not available now. If an event will happen during this half-hour, UPDATE is followed by ASSESS.

ASSESS (Figure 6.11 below) describes how the operator predicts the effect of a predicted stage change on power usage (when a furnace changes from one stage to another which uses a different amount of power).

ASSESS is linked to from (i.e. this behaviour is done during) both Figure 5.3 (UNACCEPT) and Figure 6.10 (UPDATE), so the behaviour needs to be independent of the point at which it is called on. There needs to be goal-means independence. More on this in Section 7.

It also, like 'routines', ends by returning to the point at which it was called on.

Figure 6.11 : ASSESSing the effect of a step change in power usage (Bainbridge 1972, Figure 7.2.6).

6.a and 6.b (shown below) describe 'routines' linked to from ASSESS.

Routine 6.a (Figure 6.12) describes the information the operator gathers to assess the control state after a predicted event. He finds out how big the power use change will be at the event, also how much time will be left in the half-hour after the event, and combines those in a judgement about the effect of the change.

Figure 6.12 : 'routine' 6.a which is part of assessing the control error after a predicted event (Bainbridge 1972 Figure 5.9).

That judgement is returned to ASSESS (Figure 6.11) where, if the control state after the event will be acceptable he just comments that it will be. If it will not be acceptable, what he does next depends on the current control state.

If both current and future control states are unacceptable, he notes that the future event will not compensate for current problems.

If the present control state is acceptable, and the predicted control state after an event will not be acceptable (see ASSESS in Figure 6.11), then the operator uses 'routine' 6.b (Figure 6.13 below) to think about a future action :

- if the power usage after the event will be too high, the operator decides he will cut off power to the furnace when it changes,

- if the power usage after the event will be low, that means he can increase power to a furnace which currently has a cut in its power supply.

Figure 6.13 : 'routine' 6.b which is part of choosing a future action (Bainbridge 1972, Figure 5.9).

All this is part of the review of the current control situation, started from ONGOING, see repeated Figure 5.7 above.

Routines 6.a and 6.b only occur in one context, as part of ASSESS, so they don’t need to be described in a generalised way. ASSESS and it’s associated sub-routines could have been combined in a single diagram, but it would be rather unwieldy :

Figure 6.14 : ASSESS and its associated routines.

-

Updating as an explicit strategy leads to a mechanism for one type of cognitive error. If the decisions for choosing what best to think about next have not led recently to doing this updating, then the working storage representation of the state of the task may not be valid. For example, in another study of process operation, an operator turned a control down when it should have been turned up. Without evidence about his previous cognitive activity, this would have appeared completely irrational. However, the operator had previously predicted that when a particular event occurred in the future, it would be necessary to turn the control down. In the period intervening before the event, he had been too busy with other activities to notice that something else had happened, which changed the situation so that the preplanned action was no longer appropriate. As is often the case with human cognitive errors, a mechanism which usually increases behavioural efficiency occasionally gets caught out.

-

In summary, this section has suggested two general mechanisms for updating the data in working storage.

1. The representation of the general state of the task environment is updated by special purpose 'sequencers' when the current control state is acceptable (Section 6.4.2).

2. The main task goal is checked more frequently (Section 6.4.1). It is often done after completing one part of the general state updating. The timing of this updating might be controlled by such mechanisms as :

a. the urgency of the control state setting a time control on how long the person thinks about other aspects of the task before returning to check the control state.

b. the representation of the control state decreasing in certainty over time. After meeting each cognitive need the working storage representation of the control state would be checked, and if this internal representation is too uncertain, then an explicit external check of the control state is made.

These mechanisms may be sufficient to account for this operator's behaviour in the furnace power control task. It is important to remember however that this task is simple to update. There is only one main control variable, the electric power usage, which develops in a fairly predictable way. Other aspects of the process state evolve slowly, and this evolution can also, within limits, be anticipated. I have not looked into how to expand the mechanisms discussed so far so they would deal with multidimensional sampling. I assume that the extended mechanisms would be related to those for multi-tasking, which is mentioned in Section 7.

-

6.4.3. Mechanisms for handling interrupts

There need to be at least two additional mechanisms to account for other aspects of keeping up with the state of the external world.

In the furnace task, the operator usually only noticed changes in the process state when he actively looked for them, which is accounted for by the mechanisms in the relevant sequencers and their associated 'routines'. However, he did also react to interruptions, for example he checked what was happening when he heard the teleprinter, see below. An organism which only noticed what it was interested in or expecting would not live long. There needs to be a mechanism by which salient unexpected changes in the environment can override current processing (of course this is the main reaction mechanism for most organisms). And for how the person keeps track of where they are in the main task, so they can return to it after dealing with the interrupt. (This override is indicated in the general 'overview model' diagram e.g. in the lower left of Figure 4.6.)

Figure 6.15 : An example of recovery from an interruption (Bainbridge et al, 1968, Figure 8).

The teleprinter gives information about the first basket loaded to furnace C, while the operator is currently thinking about events on furnace A.

'It’s not important’ is a comment from the observer-researcher.

Another interesting type of interrupt was noticed by Beishon (1969), who called it serendipity. This appears to take at least two forms : while looking at or for information needed for one aspect of their task, a person may notice something which is either :

(a) relevant to, and affects their thinking about, another aspect of the task, or

(b) explains a previously noticed but unexplained event.

Previous Sections have suggested that working storage maintains an overview which is a summary of data describing the main aspects of the task. Observations of this 'serendipity' suggest that the main cognitive needs may also be active when they are not explicitly being thought about, or at least not explicitly being mentioned in a verbal protocol.

-

6.5. Working storage capacity

No direct measures were taken in the furnace power allocation task about the number of items which can be held in working storage - its capacity.

It is only possible to make a few speculations about this based on the box diagram simulations of the cognitive processes involved.

In his studies (see Figure 6.7) Sperandio (1970) found that the number of items remembered by an air-traffic controller about a particular aircraft depended on how important the aircraft was in the current thinking. As commented above, those findings might be accounted for by short-term memory models current at that time, in which remembering an item depends on recency and rehearsal.

But the data from Bisseret’s study, see Figure 6.5, show that experienced controllers remember much more than suggested by laboratory memory studies. They could recall on average 33 items about the aircraft they were controlling. The evidence on how these items were remembered suggests that these items are remembered in a related way which probably cannot be reduced to a small number of independent chunks. As another piece of anecdotal evidence, air-traffic controllers talk of 'loosing the picture' as a whole, rather than individual items.

This led to a discussion in Section 6.3 that memory might be structured and aided by its position in the processing that constructed it. In more detail, Section 3 suggested that the 'routines', knowledge bases, and cross references in working storage make a mutually reinforcing redundant structure which supports the working storage. This might enable working storage for task related data to have a larger capacity than is found in laboratory studies of memory for independent context-free items.

It is a pity that there are not many studies of memory capacity for meaningful material in complex tasks.

Is there any evidence on such issues from the furnace power control study ?

Anything on memory capacity has to be inferred (like the above comments on knowledge bases in Section 3d) from the analyst’s simulation of the verbal reports, actual memory data was not collected.

Evidence from the furnace power control study suggests that the main results, found by the main 'routines', may be available for a longer period of time than just during the 'routine', as they may be referred to by other 'routines' or sequencers. This has been called continuing working storage or the overview. On the other hand, the working storage items within a 'routine' appear to be referred to only during that 'routine', this type of local storage is temporary. If cross references are only to within a 'routine', this might be more evidence to suggest that a 'routine' is an independent processing module. This is discussed more in Section 8.2.

It is possible to make some counts from the box diagrams of the number of items which need to be in working memory to do the cognitive processing.

However, most of the box diagrams for the 'routines’ are incomplete. As mentioned in Section 2, to simplify the diagrams, only the 'right side' boxes are included. The 'left side' boxes, which contain the context information, are not included.

The ’sequencer’ diagrams do explicitly contain the context information, when it is obtained by cross reference to other processing, see e.g. Figure 6.3.

The main sequencer which involves a large number of items is ONGOING (Figure 5.7 and above), which reviews the main state of all the furnaces and their power demand present and future, and does provide much of the contextual information referred to by other processes. Keeping a record of this may involve about 12 items.

For what they are worth, these counts (reported in Bainbridge, 1972) suggest there are about a dozen continuing items (see Table 4.4 column B), but that the number of temporarily stored items actively needed during most aspects of the furnace task processing appears to be within 7±2, which is the short-term memory capacity found in laboratory studies.

-

Summary of main points in Section 6

* Working storage contains the result of the thinking which meets a cognitive need, so contains transformed data/ a construct, not simply a direct representation of the outside world.

* Working storage can contain multidimensional constructs, and relations between variables.

* Sequencers contain the results of meeting the main cognitive needs, which provide an overview of the task.

* Updating the data in working storage about the general state of the task, and about the state of the main task goals, is organised by the 'sequencers'.

* Working storage for items used only within a 'routine' is temporary, these items are only available for cross reference during the 'routine'.

* Working storage for the results of the main 'routines', which is kept in the 'sequencers', is available continuously for reference by other aspects of processing, The main data items in the working storage boxes in the 'sequencers' form a general overview of the state of the task, which is continually available to all processing.

* In a dynamic task, 'sequencers' and 'routines' may be interrupted to check the state of the main task goals.

* Mechanisms are also needed for the way :

- highly salient environmental information can override the overview and its control of processing,

- people can return to where they were in the task that was interrupted.

- people can notice information relevant to parts of the task they are not currently consciously thinking about,

* The total number of items that can be recalled by experts about what is happening in a complex dynamic task may be larger than the memory capacity found in laboratory studies of short-term memory for context-free material.

* Cross references between working storage items within 'routines' and 'sequencers' also link them together.

* The cognitive needs and the cross references structure the working storage. This might help with both :

- providing a task context,

- enabling more memory capacity.

©1998, 2022 Lisanne Bainbridge

Access to other papers on this site from the Home page

In this review, there are 3 main groups of topics.

1. Introduction.

Basic element, sources of data which meet cognitive needs.

2. The cognitive processing element.

Meeting an information need :

3a. by finding it in the environment.

3b. from a stored knowledge base.

3c. by working through a 'routine',

or referring to the result of using a routine elsewhere.

Choosing what to do.

4. Sequences of activity, introduction to the 'overview'.

5. 'Sequencers'.

Choosing how to do it.

7. Choosing the method used to meet a task need :

using meta-knowledge, implications for mental workload.

8. Learning and modes of processing : some issues and possibilities.

9. Final comments.

Comments

Post a Comment